Copper Range

Copper’s unique combination of beauty and usability, together with its excellent corrosion resistance have made copper one of the most widely used industrial and architectural metals.

A truly unique pure metal that has been used since prehistoric times. Providing exceptional lifecycle cost, copper offers colour depth that change with the environment. See below for more information about the properties of copper, some history and why Continuous Group and our customers absolutely love and trust this noble metal for rain water systems.

Copper Material details.

4000-6000 year old copper spear head found in 2014

Brief history of copper.

The element copper has been an essential material to humankind since prehistoric times. In fact, one of the major ‘ages’ or stages of human history is named after a copper alloy “The bronze age”. In the history of copper, one can follow human progress.

Copper was the first metal we used in any quantity. The earliest people working with copper soon found it could be easily hammered into sheets, and the sheets in turn worked into shapes that became more complex as their skill increased.

The objects made by these early workers—such as arrow and axe heads, saws, scrapers and cutting tools—were much more reliable than those made from stone and flint. They were tough, and did not shatter easily, and this was a massive step forward.

After the introduction of bronze, a wide range of castings also became possible. Artefacts found show our strides in metal-working, culminating in the priceless inheritance of the Renaissance craftsmen. Copper and its principal alloys—brass and bronze—have always been more than a means of decorative embellishment.

Although iron became the basic metal of every Western civilisation from Rome onwards, copper metals were used when strength and durability were required. The ability to resist corrosion ensured that copper, bronze and brass remained as both functional and decorative materials during the Middle Ages and the successive centuries through the Industrial Revolution and on to the cutting-edge innovations of today.

Halo 150 and FS-80 downpipes in pure copper. 10 year patina showing a chocolate brown Colour - Nelson, New Zealand

Natural self protection

The oxidation process that gives Copper its characteristic brown / green patina is a result of exposure to the atmosphere in the location that it is installed. This process can vary due to the various pollutants that it may come into contact with. This patina eventually covers the surface and adheres tightly to it, thus providing a protective layer against further weathering and corrosion. As this is a natural process dependent on the location of the Copper and the conditions that it is exposed to, one could say that the slow but constant change to its aesthetic appearance will blend naturally to the elements over time.

Copper blends well with other natural materials like schist, untreated cedar & limestone.

It is estimated that 80% of all the copper ever mined is still in use today

Sustainability

COPPER AS A SUSTAINABLE SOLUTION :

Copper has excellent credentials as a sustainable solution. It offers an incredibly long service life and is 100% recyclable with a high residual value at it’s conclusion. Hardly any commonly used building material carries a higher financial incentive to recycle, which results in waste being avoided in every facet of it’s use. It is estimated that 80% of all the Copper ever mined is still in use today.

Copper Gallery

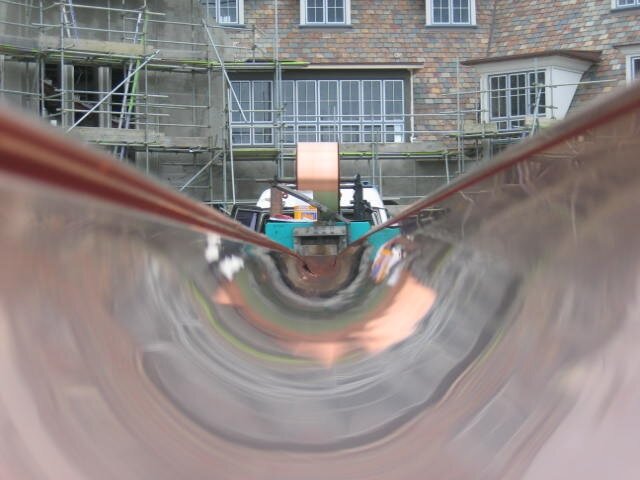

Halo 150 copper spouting roll-formed onsite

— Renovation, Christchurch